Fiberglass is quickly taking the lead as the material of choice for many construction projects. They are employed in nearly every aspect of the building, from intricate interior design to supporting columns. This is a result of their durability and adaptability. In addition, it demonstrates exceptional strength when combined with other substances. This blog is about Fiberglass Sheet: Meaning, Characteristics, Types and Uses.

In this blog, let’s investigate fibreglass sheets in greater detail and discover why and where they are utilized for various construction projects.

What Is a fiberglass sheet?

A composite material made of fragile glass fibres is called fiberglass. These glass fibres are usually woven to create a fabric resembling a mat and then strengthened with plastic. Strength, durability, and flexibility are characteristics that the final product’s material will eventually share with both plastic and glass. Therefore, glass-fiber-reinforced plastic (GFRP) or just glass-reinforced plastic (GRP) is another term for fiberglass.

Main Characteristics of a Fiberglass Sheet

The following are some of the main qualities of fiberglass sheets that have contributed to their popularity as a building material:

- Strong and long-lasting

- Rigid

- Lightweight

- Fire resistant

- Insulation material of exceptional quality

- Strong Chemical resistance

- Excellent corrosion resistance

- Material with dimensional stability

- Temperature and humidity variations have little effect on it

- It is resistant to warping, bending, deformation, and shrinking

- Resistant against moisture

Six Uses of Fibreglass Sheets in Construction

Here are the popular applications of fiberglass sheets in construction:

Fibreglass Conduits: Conventional conduits are primarily composed of heavy PVC or metal and are prone to corrosion. Fiberglass conduits, on the other hand, are corrosion-free and lightweight. Therefore, they are the ideal option for indoor and outdoor applications.

Fiberglass Composition Roofing: Fiberglass roofing has gained popularity for residential buildings due to its durability and ease of maintenance. Additionally, they outperform traditional roofs since they offer superior insulation. Furthermore, because fibreglass composition roofing can be recycled, it is more environmentally friendly, which appeals to people who care about the environment.

These roofs are a popular option because they are reasonably priced and resistant to inclement weather. They can also be reprocessed and have a longer shelf life. Additionally, they provide superior insulation compared to traditional and typical roofing materials. The fact that they require less upkeep is another plus.

Heat and Fire Protection: Fiberglass can endure temperatures of up to 1000 degrees Fahrenheit and has excellent thermal qualities. It also conducts less heat than other materials. They are, therefore, perfect for structures where fire safety precautions are required.

Earthquake-Resistant Bricks: Fiberglass interlocking bricks are a workable way to build sturdy homes in seismically active places. Fiberglass bricks have built-in bonding properties, unlike regular bricks, which need to be bound externally using cement or other materials.

Transparent Screens: Fiberglass interlocking bricks are a workable way to build sturdy homes in seismically active places. Fiberglass bricks have built-in bonding properties, unlike regular bricks, which need to be bound externally using cement or other materials.

Rust-Proofing Structure: Fiberglass sheets don’t fade or crack over time like traditional metal sheet roofing. They are fragile and made to resist strong winds, rain, and hailstorms, among other things. Above all, they are resistant to corrosion and do not rust.

Different Types of Fibreglass Sheets

Learn about the six different types of fiberglass sheets and their popular usage areas.

Fibreglass Wool: Glass fibre is used to make the lightweight, insulating material known as fibreglass wool. They are easy to handle and install. They are grouped into wool using a binder. In addition to their usual application in insulating building walls, ceilings, and roofs, they also aid in the prevention of heat transfer. In residential buildings, fibreglass wool is most frequently utilized.

E-Glass (Electrical Glass): This most common type of glass fibre is renowned for its ability to conduct electricity and its insulation properties. Circuit boards and electrical insulators frequently use it.

S-Glass (Structural Glass): S-glass is more elastic and has a higher tensile strength. They are frequently employed in aeronautical and military applications because of this.

C-Glass (Chemical Glass): Compared to E-Glass, this is more resistant to chemical corrosion. It functions best in environments where strong chemicals are used frequently, including in the production of chemical storage tanks.

A-Glass (Alkali Glass): A-glass is frequently used in situations where it may come into contact with alkaline substances since it is resistant to alkali conditions.

HR-Glass (High Resistance Glass): Absorbing up to 800 degrees Celsius, the HR glass is free of fluorine, boron oxide, and alkali. Their resistance to heat shocks is quite great.

Uses of Fiberglass in Buildings

Fibreglass is commonly used in buildings for the following purposes:

Fibreglass Windows: These days, it’s common to see these windows in offices, retail spaces, and other commercial buildings. They are well-liked because they require little upkeep, offer effective insulation, and are weather-resistant.

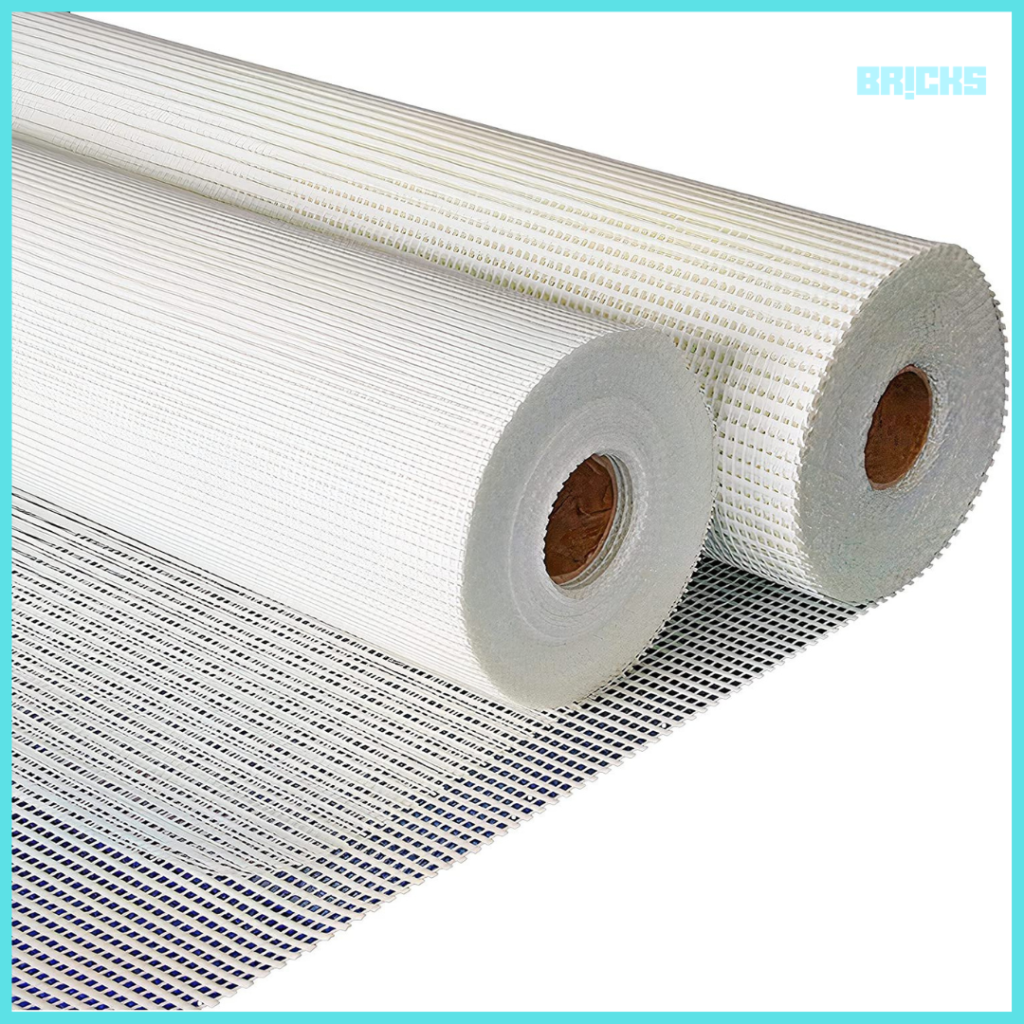

Fibreglass Mesh for Plastering: One inexpensive, non-combustible material is fibreglass mesh. As a result, it’s mostly utilized for internal wall and ceiling surfaces as well as plaster facade construction. They can be painted to get the desired appearance and come in a variety of colours.

How Fiberglass Sheets Are Made

First, raw ingredients, including limestone, silica sand, soda ash, and other additions like syenite, alumina, borax, kaolin clay, magnesite, nepheline, feldspar, and alumina, are carefully chosen and processed to begin the manufacturing of fibreglass. Cullet, another name for leftover glass, has potential uses as a raw material.

Batching of fibreglass: These parts are measured precisely before they are inserted into a furnace. After that, they are combined—a process known as batching. This guarantees that the composition is accurate and satisfies the required requirements.

Melting of Fiberglass: The furnace is essential for melting these raw materials into molten glass since it may achieve temperatures of up to 1,371 degrees Celsius (2,500 degrees Fahrenheit). Precise temperature control is maintained to guarantee a continuous and smooth flow of molten glass.

Fibre Formation: The molten glass is routed through several shaping processes based on the type of fibreglass that is required. There are various ways to create fibres, including the direct melt approach. In this method, molten glass is turned straight out of the furnace into fibers, or 1.6 cm (0.62 in.) glass marbles are used to inspect for flaws visually.

Continuous Filament Process: The continuous process produces an endless length of fiberglass filaments. High-speed winders catch the strands as the molten glass passes through the bushing and quickly wind them. The process produces yarn made of fiberglass.

Staple-Fiber Process: In the staple-fibre process, molten material passes through microscopic holes to generate long, thin fibres that form slivers that are woven into yarn by a compressed air jet.

Summary of the Fiberglass Sheet

Fiberglass is a very adaptable building material with the strength of metal and the insulating qualities of wood. It can be fashioned and sculpted in a variety of ways to meet certain needs. Its long lifespan and cheap maintenance requirements are among its other advantages. To make use of fibreglass’s many advantages, think about integrating it into your architectural design if you’re developing a new project.

Also Read: French President Emmanuel Macron House: Élysée Palace of Chief Guest for Republic Day 2024

Similar Topics: Enamel Paint: Types, Uses, Characteristics and How to Apply